Delivering Essential Water Infrastructure for Australia’s Biggest Public Transport Project

The NSW Government is delivering Sydney Metro West – a new underground metro railway which will double rail capacity between Parramatta and the Sydney CBD, transforming Sydney for generations to come. Sydney Metro West was also declared a Critical State Significant Infrastructure (CSSI) by the Minister for Planning & Public Spaces.

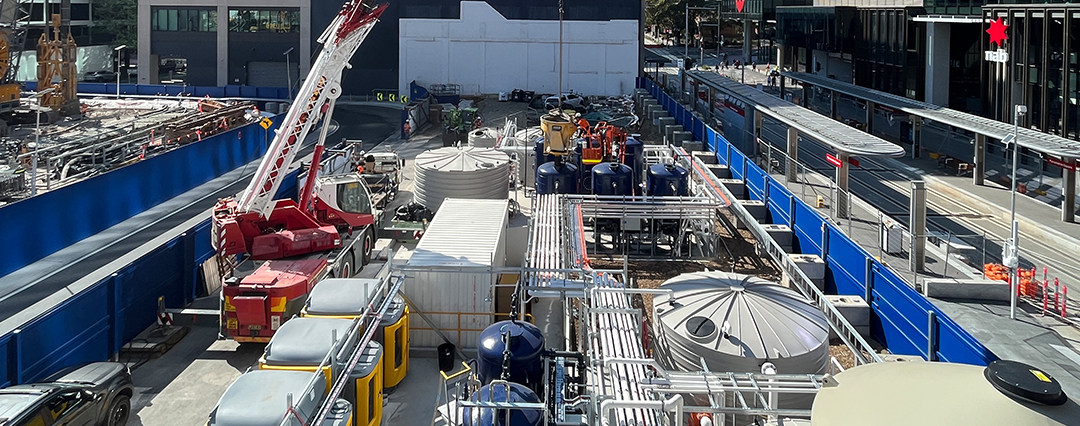

Hydroflux has successfully delivered three water treatment plants on the Sydney Metro West – Western Tunnelling Package that treats a wide range of raw water generated during the construction phase of the tunnel. The key objective of the treatment plants is to process groundwater and surface water for either onsite recycling or environmental discharge.

“We are proud to be supporting another State Significant project in the design, delivery and hand over of these three construction water treatment plants for what is another complex construction application. This brings the number of tailored solutions we have supplied and successfully commissioned in recent years to 24, with an additional nine more coming online throughout 2024. Our team has been involved in almost all major tunnelling projects across the eastern seaboard over the past 25 years and are well established as the leaders within the sector” said Mathew Foster, CEO of Hydroflux Industrial.

“Instrumental to the successful delivery of a construction water treatment plant is the ability to take our well proven TunnelMAX® and TunnelMATE® systems and add processes such as HyPURE® and HyX™ to increase the system’s ability to management emerging contaminants, whilst maintaining reliability during fluctuations in flow and load to ensure compliance with Environment Protection Licences and key stakeholder expectations.”

Two sites treat the influent water to meet the requirements for discharge the stormwater network and include:

- Selected pre-screening to suit the nature of the site.

- Water accumulation and balancing, allowing a consistent feed to the treatment process.

- Chemical pre-conditioning;

- Tailored pH correction

- Coagulation utlising selected HYDRAPRIME® coagulant

- Flocculation blending specialised HYDRABOND® polymers in a HydaBLEND® system

- Clarification with a HySEP lamella clarifiers built for construction sites

- Solids management and dewatering with HUBER Inclined Sludge Press

- Chemical storage and dosing tailored and arranged to suit the site layout and access

- Specialised polishing steps using HyPURE® media filtration and HyX™ Ion Exchange for one site with extremely tight limits for PFAS and nitrates, including our proprietary regeneration process

- Hybrid BWRO/SWRO ultra high recovery HyPURE® Reverse Osmosis to manage a highly variable TDS profile and achieve an extremely tight discharge limits on conductivity

The third site treats wastewater generated from the construction of pre-cast concrete segments to enable 100% reuse within the production process. The main treatment processes used in the wastewater treatment plant are:

- Pre-screening and conical balance tank

- Chemical pre-conditioning;

- Tailored pH correction

- Clarification with a HySEP built for construction sites

- Solids management and dewatering with HyPRESS Belt Filter Press

- Chemical storage and dosing tailored and arranged to suit the site layout and access

- Specialised polishing with media and activated carbon adsorption

By tailoring each plant around our modular TunnelMax® and TunnelMate® systems, Hydroflux offers targeted treatment that has been value-engineered to suit each site and application.