Compact Packaged Inlet Works System for Pemberton WWTP

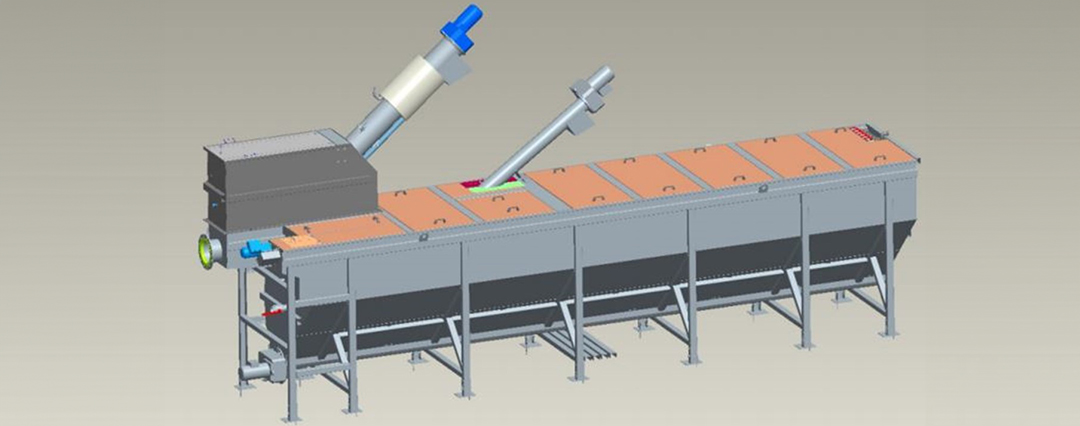

The Pemberton WWTP was recently upgraded to increase capacity and discharge quality. Part of the upgrade included a HUBER Ro5 Packaged Inlet Works.

The system removes screenings, bags, plastics and sand from the raw sewage flow, prior to treatment in the downstream process.

Being a package system, fully fabricated from stainless steel, site installation time and cost is reduced as compared to traditional inlet works that use suspended concrete structures.

The benefits include:

- High screening efficiency and capture due to perforations

- High efficiency grit removal system

- Integrated screenings compaction

- Integrated bypass chamber with manually rake bar screen

- Fully enclosed and guarded

- All stainless steel fabrication

The packaged system consists of an inlet screening chamber which is fitted with a HUBER Spiral Screen, and then a horizontal grit removal chamber.

These are both housed within a single stainless steel tank, that is provided with influent and effluent flanges, support legs and chutework to direct the captured by-products to the associated disposal skips.

To facilate odour control, the tank is fitted with odour extraction ports and the byproducts are discharged into seal bags for offsite disposal.

“A traditional inlet works requires the design and construction of a suspended or below ground concrete structure, depending on the site.

At flows below 10MLD, it is more economical to use a HUBER packaged inlet works system, as the design and hydraulic layout is catered for by Hydroflux Huber and only minor site works is required to install the system” says John Carroll, Director of Hydroflux Epco.

| Item | Value |

| Max Capacity | 50 L/s |

| Screen Aperture | 6mm |

| Headloss | 250mm |

| Solids Compaction | 35% dry solids |