Energy Saving Aerostrip® Diffusers for Bunbury WWTP

AEROSTRIP® Membrane Diffuser technology was developed to provide the most energy efficient process for providing oxygen to aerated biological processes.

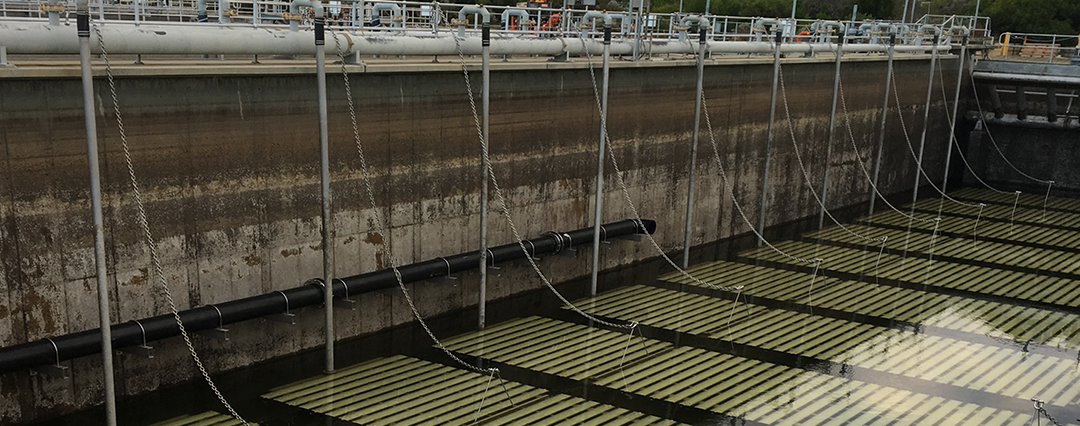

Water Corporation’s Bunbury WWTP recently underwent an upgrade to replace some older assets within the site and increase plant capacity. The process includes a fine screen facility, grit removal, 4 x SBRs, sludge plant and effluent disinfection. Over 2000 AEROSTRIP® diffusers were delivered to be fitted to the four SBR reactors. The AEROSTRIP® units were fitted to removable frames to enable lift out for inspection purposes.

The Project

Hydroflux worked with Water Corporation to enable a cost benefit analysis across multiple diffuser floor densities, air flow, energy consumption and subsequent life cycle costs.

The installation shows that increasing floor density can provide a life cycle benefit when both the capital and operating costs are taken into consideration. The unique micro perforations provide a 1mm bubble size, which in turn maximises mass transfer efficiency of oxygen.

SAE’s of 4.5—5.5 kg O2/kW are achieved with AEROSTRIP® diffusers and both clean water and off gas tests have demonstrated this performance and new and existing installations.

The Outcome

Some of Australia’s largest treatment plants have now installed AEROSTRIP® diffusers, with enough energy savings over conventional circular disc units to power thousands of houses.

| Item | Value |

| Plant Capacity | 13 MLD |

| Number of Diffusers | 2288 |

| Diffuser Length | 3M |

| Process Type | SBR |

| Bubble Size | 1mm |

| Material | Polyurethane membrane |