High Efficiency Screening Technology for Lowood STP

The Lowood STP was recently upgraded to include a new modern screening facility supplied by Hydroflux Epco.

Project Overview

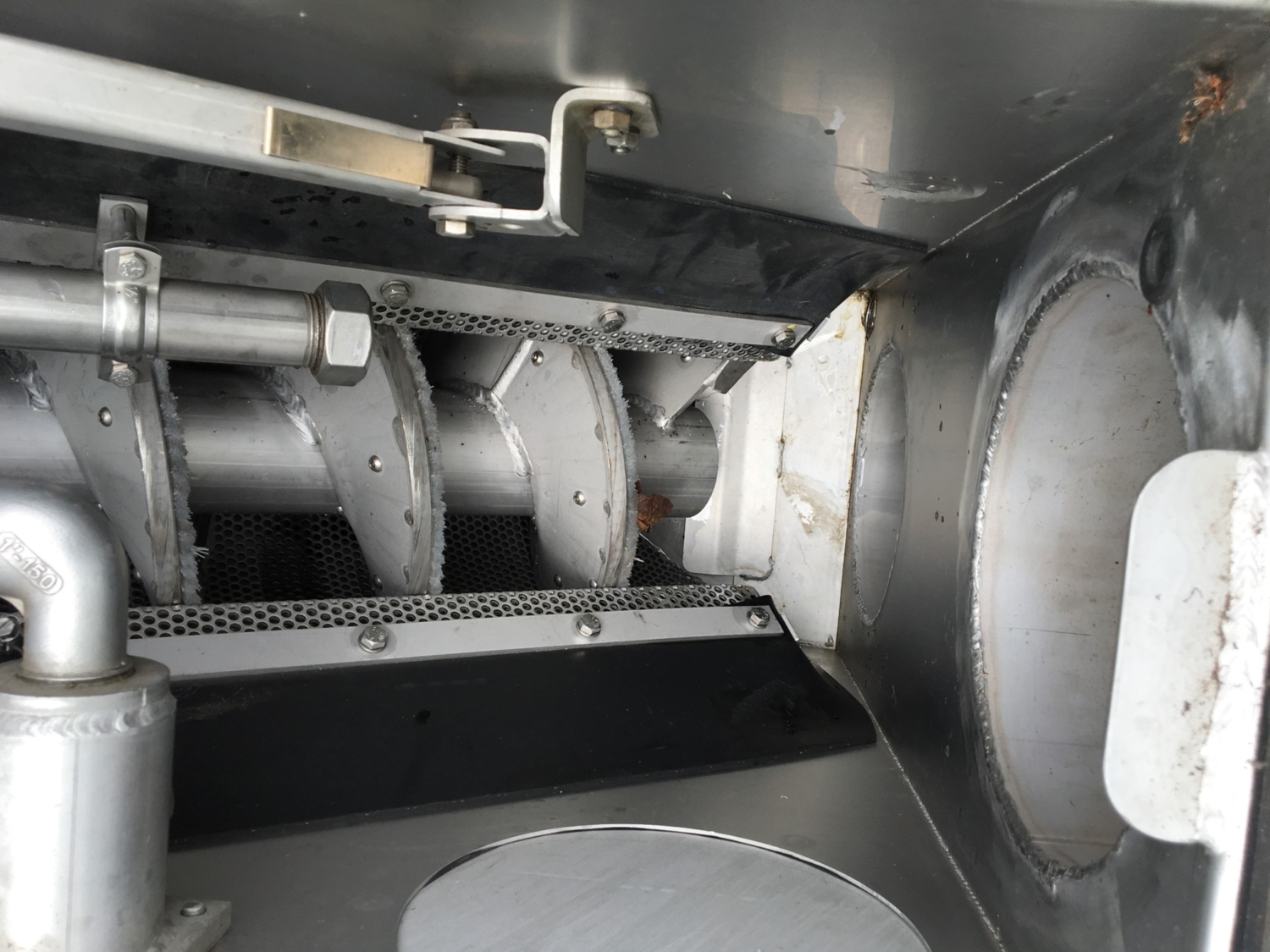

Sewage from the catchment is pre-screened for removal rags, plastics, bags and gross solids. All solids that are removed are compacted prior to discharge to a bagging unit, which provides a hygienic method for collection of the screenings.

The benefits include:

- High screening efficiency and capture due to perforations

- Reduces maintenance costs associated with downstream equipment (sludge basins, digesters)

- Integrated screenings compaction

- Fully enclosed and guarded

- All stainless steel fabrication

The installation results in the removal of solids and screenings, that would otherwise accumulate in the downstream activated sludge plant and digesters.

Maintenance costs of the downstream process are significantly reduced.

To facilitate site installation the screen was provided with its own stainless steel influent channel, that includes a bypass offtake.

A local control panel provides automatic unattended operation of the screen. Operation is based on the upstream water level within the tank, which means that the screen only works when it has to. This minimises wear and energy consumption.

All wetted components are fabricated from stainless steel. This includes the internal screw.

| Item | Value |

| Max Capacity | 30 L/s |

| Screen Aperture | 6mm |

| Headloss | 200mm |

| Solids Compaction | 35% dry solids |