Innovative Wastewater Treatment at Carlton & United Breweries: A Sustainable Approach with DAF Technology

Carlton & United Breweries (CUB), a historic Australian brewing company headquartered in Melbourne and now owned by the Japanese conglomerate Asahi Breweries, has long been seen as a leader in sustainable water management at its Yatala site, located just south of Brisbane. This site plays a crucial role in the brewery’s operations, which produce between 3 to 4 million litres of trade waste per day of which about 65% of this wastewater is treated and reused as process water, highlighting CUB’s commitment to environmental sustainability and resource efficiency.

The recycled water is generated at a consistent rate of 1.5 to 2 million litres per day and is employed across a variety of essential processes within the brewery. These include cooling towers, boiler feed, cleaning-in-place (CIP) systems, pasteurisation, pre-cleaning of vessels and pipes, floor washing, toilet flushing, and irrigation.

At the heart of this recycling process is a multi-barrier wastewater treatment system. This system features an Upflow Anaerobic Sludge Blanket (UASB) reactor which enables the recovery of approximately 90% of the energy present in the wastewater, which is then converted into biogas. This biogas is captured and utilised to supplement natural gas used to fire the brewery’s boilers. Additionally, a reverse osmosis (RO) system is used to remove salts from the treated water, ensuring that it meets the quality requirements for its various industrial applications.

In 2016, Hydroflux was engaged to address a specific challenge within this wastewater treatment process: the carryover of anaerobic solids from the UASB system to the downstream aerobic Moving Bed Biofilm Reactor (MBBR). This carryover was causing operational inefficiencies and needed to be mitigated to ensure the smooth functioning of the entire treatment system.

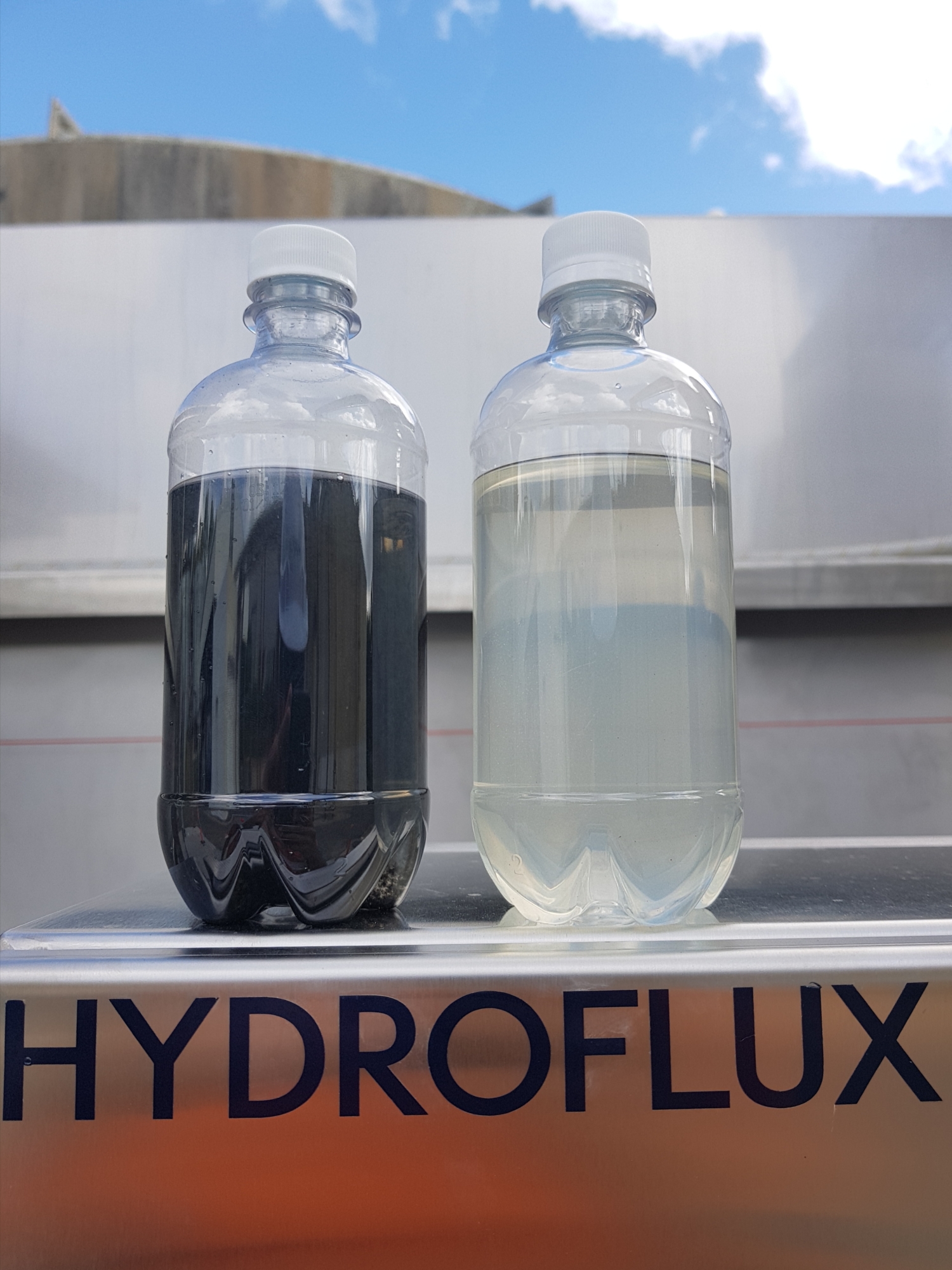

To tackle this issue, Hydroflux recommended the installation of a HYDAF HD200 Dissolved Air Flotation (DAF) system. After some initial trials, the DAF system proved to be the most effective technology for this particular application. The system was installed directly between the UASB and MBBR system and was designed with a capacity of 240 kL/hr to handle solids loads exceeding 3000 mg/L. The DAF system successfully reduced the carryover of anaerobic solids, meeting performance requirements of 30 NTU, which significantly improved the overall efficiency of the wastewater treatment and recycling process.

The installation of the DAF system was executed as a turnkey project, encompassing all civil, mechanical, electrical, and SCADA integration work and was completed within five months and became operational by late 2016. Since its commissioning, the system has consistently performed to the required standards, playing a critical role in the brewery’s continuous water recycling efforts.

This project at CUB’s Yatala site stands as a prime example of the innovative application of Hydroflux’s HyDAF system in a new context. While DAF systems are widely recognised for their effectiveness in treating industrial wastewater, sludge thickening, wastewater polishing applications, and water treatment, their successful use in removing anaerobic sludge marks a significant advancement in the field and highlights the potential of DAF technology to address complex wastewater treatment challenges.